Trusted to Protect

Industry-leading emergency warning and lighting solutions designed with your critical missions in mind, manufactured in America for more than 70 years.

Our mission is clear: to protect those who protect others. This commitment drives us to produce reliable, high-quality products that first responders and critical professionals worldwide can depend on in the most challenging situations to keep them seen, safe, and ready for anything. Every Whelen product is a testament to our dedication and is crafted with precision, rigorously tested on-site, and certified to meet the highest industry standards.

At Whelen Engineering, our legacy is built on a steadfast commitment to American innovation and craftsmanship that has endured since 1952. What began in George W. Whelen’s garage in Deep River, Connecticut, has grown into a global, industry-leading enterprise with over 70 years of proven excellence and earned trust. With cutting-edge facilities in Connecticut and New Hampshire spanning nearly 1,000,000 square feet, we design and manufacture a comprehensive range of high-powered warning lights, white illumination systems, sirens, controllers, mass notification solutions, and more.

We celebrate our heritage of American manufacturing with immense pride. We’re proud to have the largest engineering team in the industry as well as a dedicated workforce of over 1,500 employees who are the driving force behind our relentless pursuit of innovation and quality. As we continue to lead the industry, we remain steadfast in our commitment to support and empower the everyday heroes who rely on our products and technology.

Manufactured in America for over 70 years, we never left and we’re here to stay.

At Whelen Engineering, our legacy is built on a steadfast commitment to American innovation and craftsmanship that has endured since 1952. What began in George W. Whelen’s garage in Deep River, Connecticut, has grown into a global, industry-leading enterprise with over 70 years of proven excellence and earned trust. With cutting-edge facilities in Connecticut and New Hampshire spanning nearly 1,000,000 square feet, we design and manufacture a comprehensive range of high-powered warning lights, white illumination systems, sirens, controllers, mass notification solutions, and more.

We celebrate our heritage of American manufacturing with immense pride. We’re proud to have the largest engineering team in the industry as well as a dedicated workforce of over 1,500 employees who are the driving force behind our relentless pursuit of innovation and quality. As we continue to lead the industry, we remain steadfast in our commitment to support and empower the everyday heroes who rely on our products and technology.

Manufactured in America for over 70 years, we never left and we’re here to stay.

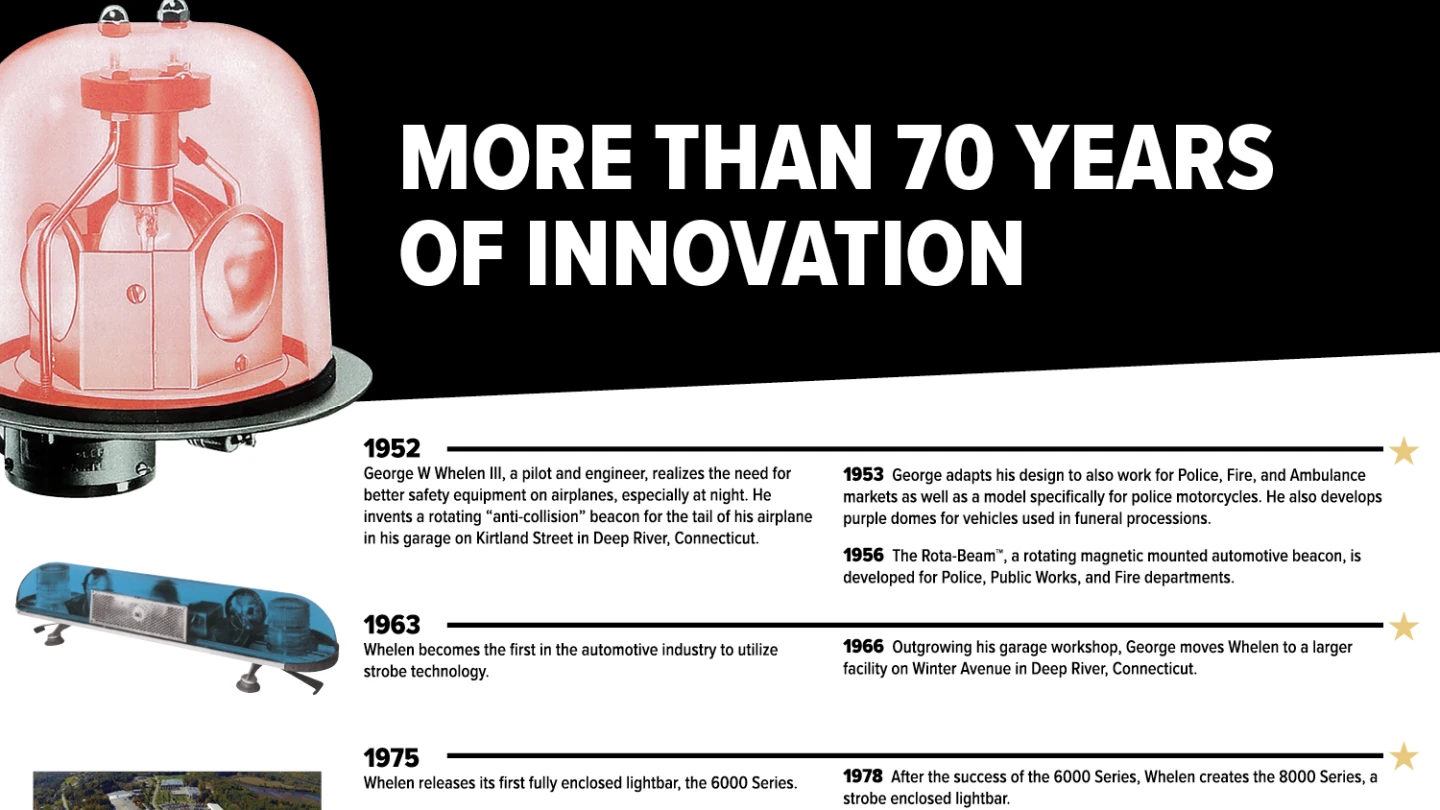

Our rich history of American innovation and craftsmanship spans from our humble beginnings in 1952 to becoming a global leader in emergency warning products and technology.

Our Values

At Whelen, we value people, act with integrity, and embrace teamwork. We’re passionate problem-solvers dedicated to innovation and exceeding customer expectations. By fostering a culture of growth, curiosity, and collaboration, we create products designed to perform when it matters most.

Value People

We invest in each other, encouraging growth, fulfillment, and fun in the workplace.

Be Kind

We share our time, skills, and knowledge, uplifting colleagues and communities.

Do the Right Thing

Guided by integrity, we value transparency, respect, and diversity, creating space for everyone to be themselves.

Own It Together

We take pride in our work, fostering collaboration built on honesty and a shared commitment to team success.

Be the Best

We challenge the status quo, stay curious, and embrace learning, constantly improving for the team’s benefit.

Lead the Way

We exceed customer expectations by understanding their needs and delivering reliable, life-saving solutions built for any road, weather, condition, or emergency scenario.

Our Leadership Team

Our executive leadership team guides a dedicated workforce of over 1,500 employees, driving innovation and excellence in every aspect of our operations.

Chief Executive Officer

Senior Vice President of Operations

Senior Vice President of Technology and Innovation

Chief Financial Officer

Vice President of Sales

Vice President of Human Resources

Vice President of Engineering

Vice President of Marketing

CEO of Whelen Aerospace Technologies (WAT)